Continuous analizers for process gas. EXTRACTIVE AND IN SITU.

ULTRAMAT 23

Multi-component design and NDIR technology for measurement of up to three active IR gases and optional electrochemical and paramagnetic cells for measuring O2.

The automatic integrated calibration function that makes use of ambient air is a unique advantage. In addition, calibration with standard gas is necessary only once a year.

High reliability and maximum response speed in conjunction with multilayer detectors guarantee high selectivity and zero interference.

Maximum number of components: 3 IR + O2.

Components: example CO, CO2, NO, SO2, CH4, O2, H2S

Minimum measurement range:

Specific for each component: 0-50 / 0-500 vpm.

Combines the productivity and reliability of gas measurements of a ULTRAMAT 6 with OXYMAT 6 in a single analyzer, guaranteed by modern electronics, high selectivity and operation ease.

Up to two active infrared components and oxygen can be measured even in complex gas mixtures, guaranteeing measurements of lower concentrations and detection limits.

Maximum number of components: 2 IR + O2

Components: O2 and active components in the IR.

Minimum measuring range: 0-0.5% O2 and depending on the IR component: 0-5 / 0-100 ppm

ULTRAMAT / OXIMAT 6

CALOMAT

For the continuous measurement of noble gases and hydrogen, the thermal conductivity of the gas sample mixture is measured and used to calculate the concentration. If more than two components are present, the concentration of others must be measured separately using other methods, but CALOMAT 6 can perform the internal correction of these and truly show the concentration of gas in its process.

Maximum number of components: 1.

Components: example H2, He

Minimum measuring range: 0-1%.

Gas analyzers with an FID (Flame Ionization Detector) are ideal for measuring total hydrocarbon.

FIDAMAT versions cover a wide range of uses even with the presence of corrosive fumes. Maximum number of components: 1.

Maximum number of components: 1.

Components: Total hydrocarbons.

Minimum measurement range: 0-10 vpm.

FIDAMAT

SITRANS SL

A gas analyzer with diode laser that works according to the NDIR principle. SITRANS is especially suitable for quick and contactless measuring concentrations of chimney or process gases. Two sensors (one sending and one receiving unit) are mounted directly in the process. For this, no sample extraction and treatment systems are needed. The sensors are designed to operate under adverse environmental conditions.

This measurement principle works almost in real time, with total precision and with hardly any disturbances caused by secondary gases, dust or aerosols. Other influences, for example variations in pressure or temperature are compensated by the device.

Maximum number of components: 1.

Components: O2.

Minimum measuring range: O2: 0-1%.

LDS 6 does not contain parts subject to wear. Its design opens new possibilities for process control and emission monitoring. The simple fact that with LDS 6 it is possible to generate process data without contact and in real time, without distortion or delay.

In addition, the rapid in situ measurement can have a positive impact on the profitability and environmental compatibility of the plant.

Maximum number of components: 2.

Components: O2, NH3, HF, H2O, CO2, CO, HCl

Minimum measurement range: Specific for each component from 0-5 ppm to 0-5%.

LDS 6

SIPROCESS GA700

The new SIPROCESS GA700 series for gas analysis offers the possibility of accommodating two modules in a housing: either in a wall mounting box or in a 19 ″ rack box with three height units, depending on the needs.

SIPROCESS GA700-ULTRAMAT 7

high measurement accuracy for complex gas mixtures according to the NDIR principle.

SIPROCESS GA700 – OXYMAT 7

for measuring oxygen concentrations.

Maximum measurement accuracy thanks to the paramagnetic method.

SIPROCESS GA 700 – CALOMAT 7

for the quantitative determination of H2 and He in binary gas mixtures and the like with thermal conductivity detector.

D-R 320 DUST MONITOR

D-R 320 is based on the principle of backward scattered light. In this way, the light of a red laser diode illuminates dust particles in the measurement volume of the combustion gas duct. The light scattered backwards by these particles is detected and evaluated.

A unique feature of the D-R 320 is the automatic backlight compensation with a patented dual detector optical system. This allows quick and easy installation without any adjustment. A light trap is not required.

Measuring range: 0… 5 mg / m³ max. 0… 200 mg / m³. Concentration: 0… 7.5 mg / m³.

Concentration: 0… 7.5 mg / m³.

IP protection class: (IEC 60529) IP65.

D-R 808 is a scattered light dust monitor, tested to monitor small to medium dust concentrations in dry fumes or process gases.

For the monitoring of very low concentrations, the principle of forward dispersion is ideal. Here, the modulated light of a laser diode penetrates the measurement volume in the smoke duct. A highly sensitive detector records the light scattered by dust particles in a forward direction. The measured scattered light is directly proportional to the dust concentration.

Measuring range: Min.: 0… 5 mg / m3 Max.: 0… 200 mg / m3.

Lowest certified range: 0… 7.5 mg / m3.

Measuring principle: forward dispersion.

IP protection class: (IEC 60529) IP65.

D-R 808 DUST MONITOR

D-R 290 OPACITY MONITOR

D-R 290 works using the double-pass method according to the principle of self-polymerization. The light beam crosses the measurement path twice. The attenuation of the light beam is measured and evaluated by the dust content in the measurement section.

D-R 290 has an internal reference point and zero verification, as well as pollution measurement. The pollution is compensated automatically. A maintenance demand is indicated immediately.

Measuring range:

Extinction: 0… 2.0.

Opacity: 0…100 %

Dust: 0…80 mg/m3… 0… 5000 mg/m3

Measurements: Extinction, transmission, opacity, dust concentration.

IP protection class: (IEC 60529) IP65.

Total mercury analyzer certified for the continuous measurement of mercury in chimney or process gases that allows the speciation of elemental and oxidized mercury.

With the lowest measuring range newly certified. For EN 15267 of 0… 15 µg / m³ for large combustion plants.

Elementary and rusty.

Automatic verification of the reference point with internal HgCl2 calibration gas generator.

Without extremely hot components, easy to maintain.

Automatic leak control.

Automatic zero point check with ambient air.

Automatic verification of the reference point with HgCl2 calibration gas generated with internal reference gas generator.

Manual verification of the reference point with external calibration gas generator.

Measuring range: Total Hg 0… 400 μg / m3.

Measurements: total mercury concentration Hg total after calibration with the standard reference method.

IP protection class: (IEC 60529) IP54.

HM-1400 TRX 2 HM-1400 TRX 2 TOTAL MERCURY ANALYZER

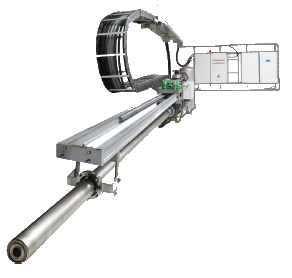

D-FL 220 FLOW MEASUREMENT

Ultrasonic measuring system tested and certified to measure the speed and volume flow of combustion gases or process gases in pipes or ducts, especially for wet and aggressive smoke emissions.

D-FL 220 measurement system operates according to the acoustic transit time difference method. Two identical transducers are sent to each other and receive short ultrasonic pulses. The system calculates the precise speed of the gas from the difference in transit time dependent on the direction. The speed of the respective volume flow of the waste gas is accurately calculated from the difference in transit time that depends on the direction.

Measuring range: 0… 3000000 m3 / h / 0… 40 m / s.

Measurements: Gas speed and direction, volumetric flow under normal conditions or operating conditions.

IP protection class: (IEC 60529) IP55.

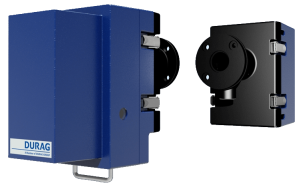

Hamburg / Aix-en-Provence, January 28, 2019 – The company AP2E, member of the DURAG GROUP, successfully obtained the QAL1 certificate for the ProCeas® LaserCEM® gas analysis system according to MCERTS. Therefore, the measuring instruments meet the high quality requirements of European standards EN 14181 and EN 15267.

AP2E gas analysis systems are used successfully worldwide for continuous emission monitoring. AP2E solutions are based on an innovative laser gas technology and a sampling system, both patented. This allows the analysis of complex and simple gas mixtures, while maintaining high selectivity, precision and stability over a wide measuring range.

Measuring gases: H2S, CH4, CO, CO2, H2, H2O, HCI, HCN, HF, N2O, NH3, O2, NO, NO2.

AP2E GAS ANALYZER

CEMTEC

CEMTEC® is a probe that can self-clean and allows a virtually continuous measurement with 95% availability. In addition to the sensors for a direct and instantaneous analysis of oxygen and COe, a gas conduction line provided with heating, allows approximately 60 l / h of combustion gas to be supplied to an extraction analyzer with which to measure various components such as O2, NOx or CO2.

Applications:

- Cement plants.

- Lime plants.

- High temperatures, high dust concentration.

Types of fuels: Coal, oil, alternative fuels.

Probe cooling method: water / water re-cooler or air / water re-cooler.

re-cooler air/water

Maximum process gases temperature

1400 °C

OXITEC® analyzers are extremely versatile and can be configured to adapt to any process: probe length, filter type, interface, and even probe material can be configured individually.

The superiority of the OXITEC® 5000 oxygen analyzers comes from a clear commitment to the use of the highest quality materials at every step of our production chain, as well as the experience and know-how of our specialists. ENOTEC produces high durability analyzers for the most demanding combustion processes, so that their need for maintenance is reduced to a minimum.

Applications:

- Optimization of fuel efficiency.

- Emission Measurement.

- Electric power generation.

- Waste incineration.

- Combustion control.

O2 Measuring range: 2 X 0 – 2% O2 up to 0 – 25% O2.

Measuring principle: Xirconium oxide for O2

Protection: IP66.

OXITEC

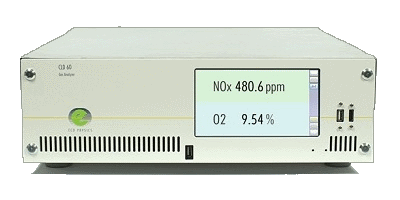

60 SERIES

CLD 60 Series Analyzers employ the chemiluminescence (CLD) operating principle. The CLD 60 series has been developed for continuous, accurate and reliable measurement in static and mobile measuring stations.

Measuring nitric oxide emissions often requires oxygen content as a reference and other measured variable For this case of application, the new series of devices is optimal. It unifies standardized chemiluminescence and paramagnetism measurement methods in a unique and compact device.

A modern graphical user interface allows operation through the touch screen. Measurement values can be stored inside the device and are available on the network or in the USB memory.

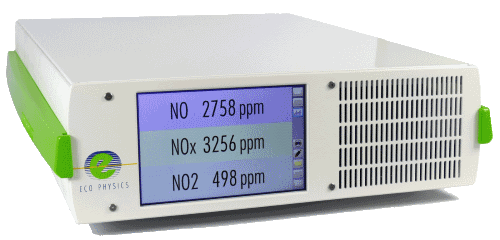

CLD 800 series is our compact, first-line NOx analyzer with vacuum pump and ozone thermal destroyer within the case of the analyzer.

We now offer a selection of converters, heated sample inlets, pressure regulation and multiple reaction chambers. CLD 800 series’ instruments are ideal for compact applications and offer advanced options for research applications.

The Eco Physics CLD 800 series is a new generation of equipment with a unique modular design. This means that each analyzer can adapt exactly to your needs. In other words, you buy what you really need. If your needs grow, the analyzer can be updated at any time.

800 SERIES

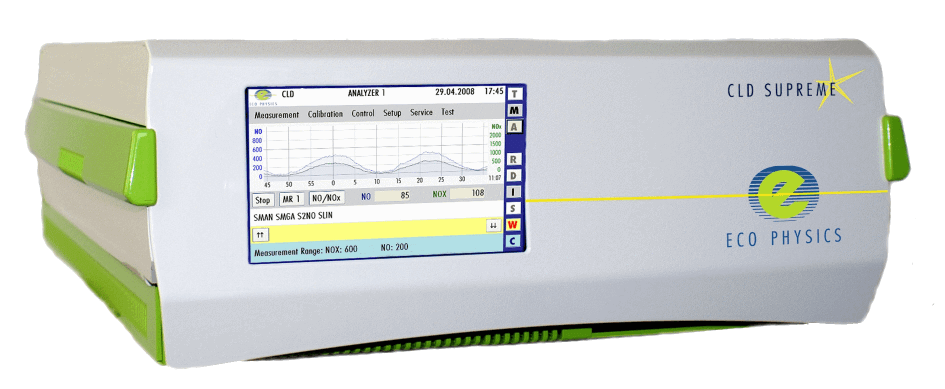

SUPREME LINE

The carefully configured CLD measurement ranges cover up to a five-digit factor. Introducing nCLD SUPREME, this is the first instrument that covers six digits of measurement ranges. In the past, applications with highly dynamic measuring ranges, such as pre and post catalyst measurements, required two analyzers. Today this task can be solved by one instrument: the nCLD SUPREME.

These qualities are the basis for the high performance of these analyzers to detect nitrogen oxides, even at ppt levels. The instruments of the Supreme Line constitute the latest range of CLD detectors from Eco Physics. Among the main features of the Supreme Line are color touch screen, one or two CLD channels with integrated pump, folding front panel for easy access and for better readability, USB connector for extracting stored data and easy exchange filter package.